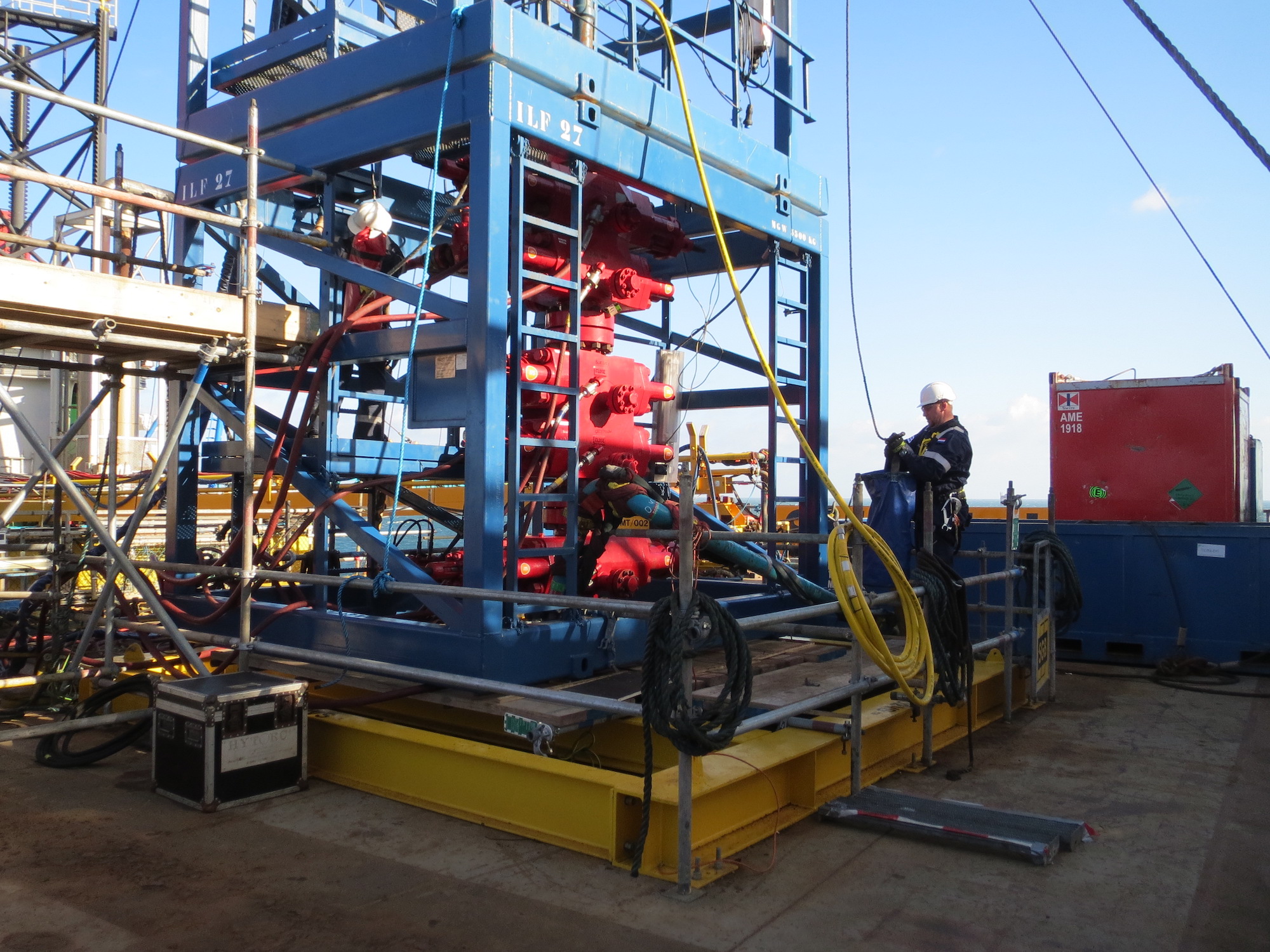

Pinnacle have provided innovative structural engineering solutions to AJS, Shell and NAM since 2011, in order to support the installation, erection and operation of coil tubing and velocity string towers on existing gas platforms, within the UK and NL waters of the Southern North Sea.

Design solutions

Pinnacle’s design solutions typically begin with the structural assessment and analysis of the existing platform’s primary and secondary structure, local to the project affected areas.

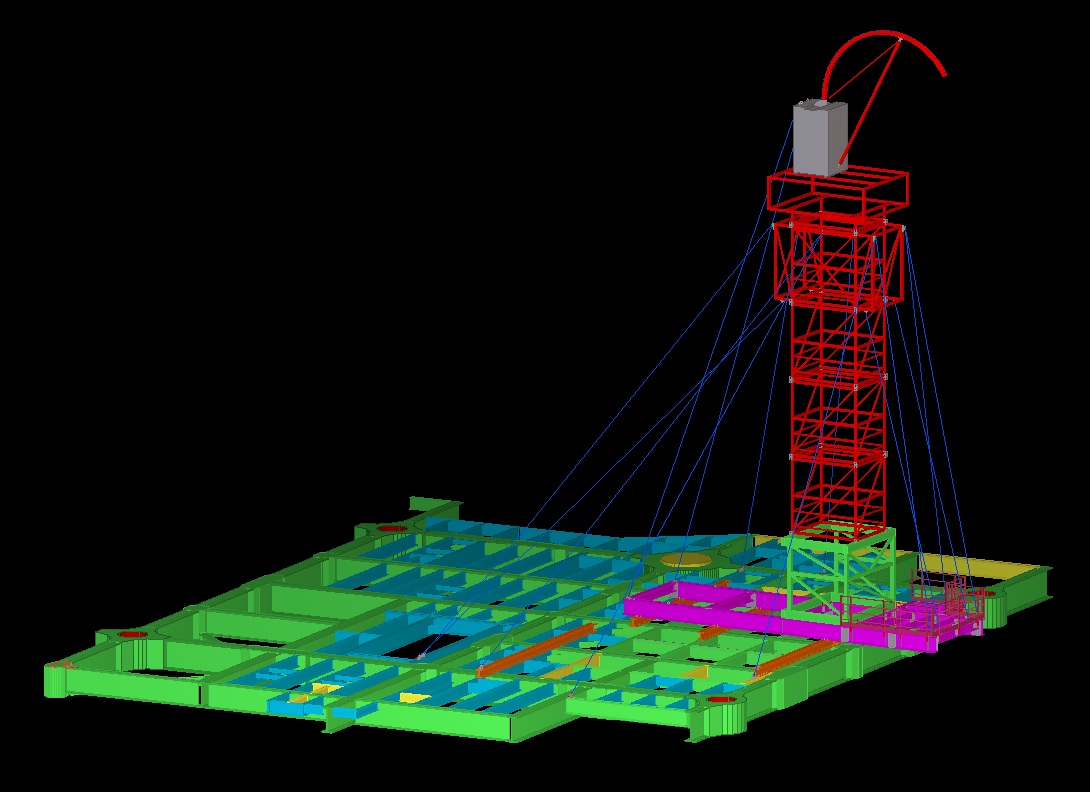

Using this analysis data Pinnacle can then design and fully detail appropriate steel spreader frames, transfer grillages and tie down points to distribute the operational, environmental and accidental loadings from the well intervention tower into the jacket structure, without causing detriment to the serviceability of the existing construction.

Fully Coordinated design

Throughout this process Pinnacle fully coordinate the design to ensure that there are no clashes with interface landing positions, project deck requirements, guy wires or platform equipment.

The design solutions developed by Pinnacle’s engineering team prioritise intelligent solutions to enable simplicity and optimum speed of the offshore installation, in order to minimise client costs and time. In order to maximise efficiency and minimise waste, Pinnacle have, wherever possible, designed solutions that allow for the re-utilisation of support spreader frames and pad-eyes on subsequent platforms and projects.

As with all of Pinnacle’s design solutions; the provision of a safe and functional working environment is the highest priority.

Throughout the process of planning and design through to construction and de-construction Pinnacle support the client’s team with a fully integrated structural engineering service.

Pinnacle are flexible, adaptable and proactive and above all totally reliable.