In 2011 Shell / NAM commenced a campaign of well rejuvenation to gas wells within the Southern North Sea, which had become closed-in and no longer productive.

In March 2013, the Seajacks Kraken visited the L13-FD-1, normally unmanned installation (NUI) gas platform, in the Dutch sector of the Southern North Sea, in order to rejuvenate 3 locked-in gas wells. The plan was to carry out a process of Coiled Tubing (CT) Clean Out followed by the installation of Velocity Strings (VS) into each of these 3 wells aiming to bring them back on line and into productivity.

To carry out the Coil Tubing Clean Out and Velocity String installation the Seajacks Kraken was used to install a 23m high, 30 tonnes, VS/CT tower onto the gas platform over the well bays, from which the well intervention work would be carried out.

The Challenge

Normally, with VS operations, the VS/CT tower would sit on a platform deck, over the well bay, utilising a spreader frame and guy wire arrangement to safely transfer the weight and environmental forces back into the platform’s main structure. The L13-FD-1 does not have a deck over the well bay, therefore fully exposing the well heads.

Pinnacle’s engineering challenge was to design a system to support the tower in 3 different positions (over 3 different wells) – this needed to be installed as quickly as possible, within the restrictions of the platform’s cranes lifting capacity. Hot-works were restricted to a minimum, drilling into the primary structure was not permitted and limited personnel were permitted on the platform at any time (whilst shuttling).

The Existing Structure

The well bay was surrounded on 2 sides by semi-clad wind protection works.

The Design Solution

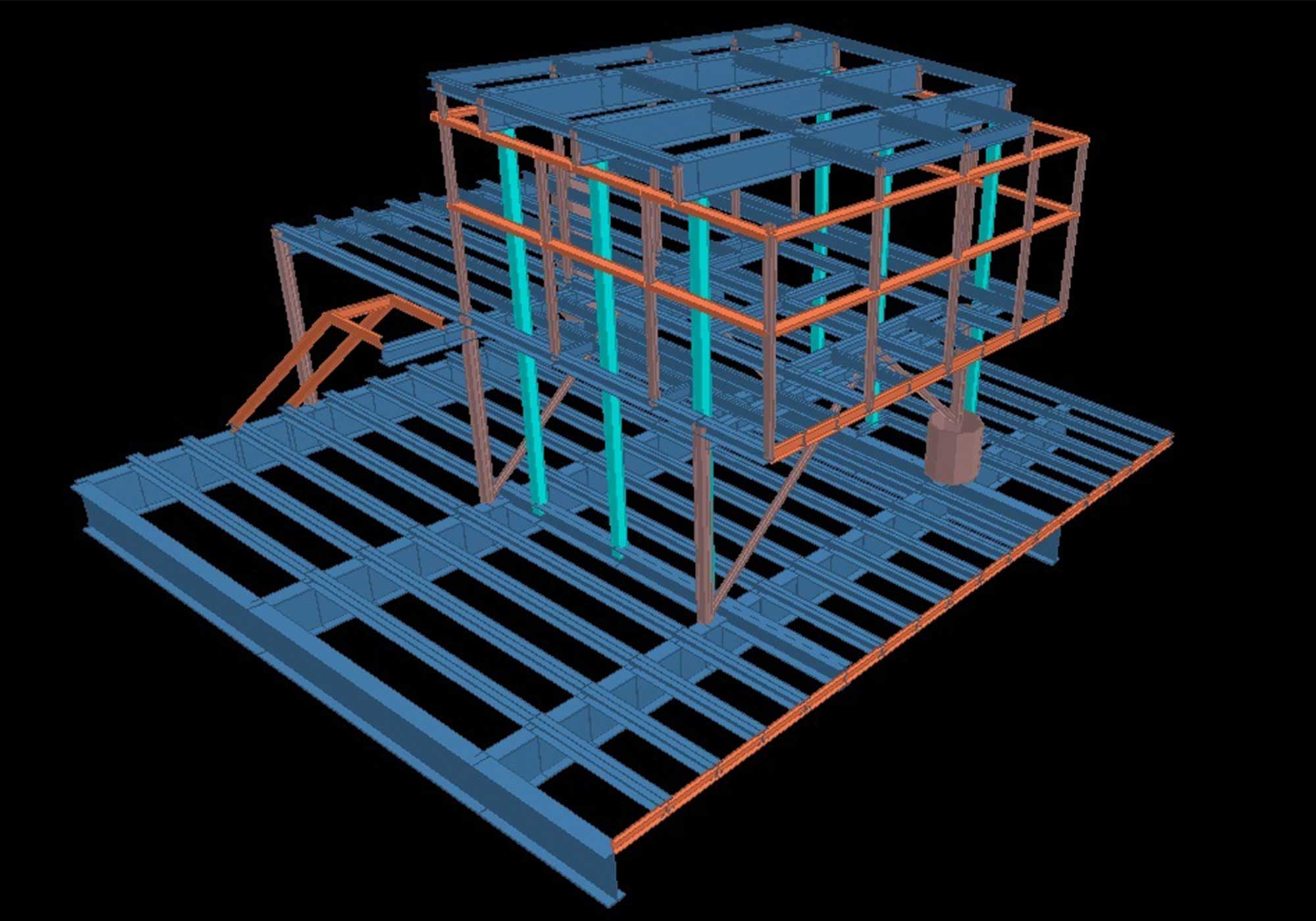

Pinnacle’s design solution was to provide a temporary steel deck structure over the well heads, with no on-site welding, and to then back prop this through the structure to the cellar deck below. This utilised the wind wall framing, already in place and supported off the weak well head service platform below, therefore requiring back propping.

Pinnacle opted to construct the new deck and support structure from the top downwards. Although this may sound counterintuitive, the solution allowed the deck to be accurately back propped through the existing structure, avoiding pipes, cable trays, well heads and flow lines, without having to try to temporarily restrain and locate props and posts.

A new steel deck structure spanning across the wind walls was designed to allow the different tower rig up arrangements needed in order to give access to the 3 wells below.

The final designed back propping arrangement comprised a combination of hot-rolled steel sections (temporarily hung from the temporary deck), which were then supported off groups of Gass Props. The props were taken down to cellar deck where local spreader beams transferred the forces into the main deck structure. The complete propping arrangement was fully coordinated, during the design stage, using data from a 3D laser point cloud survey of the platform. This coordination allowed the bracing design and setting out to avoid the numerous and complex arrangement of obstructions.

Horizontal compression bracing was designed using CHS sections. Again, this needed to be installed quickly and without site welding. Pinnacle designed and detailed a system of clamped connections that fitted to the existing CHS’s and horizontal channel sections.

The L13-FD-1 structural engineering solution adopted was delivered and constructed within a very tight programme and allowed the Coil Tubing Clean Out and Velocity String operations to take place with no hold ups, or structural issues.

At the end of the project the temporary structures were removed and the platform reinstated to it’s existing structural condition.